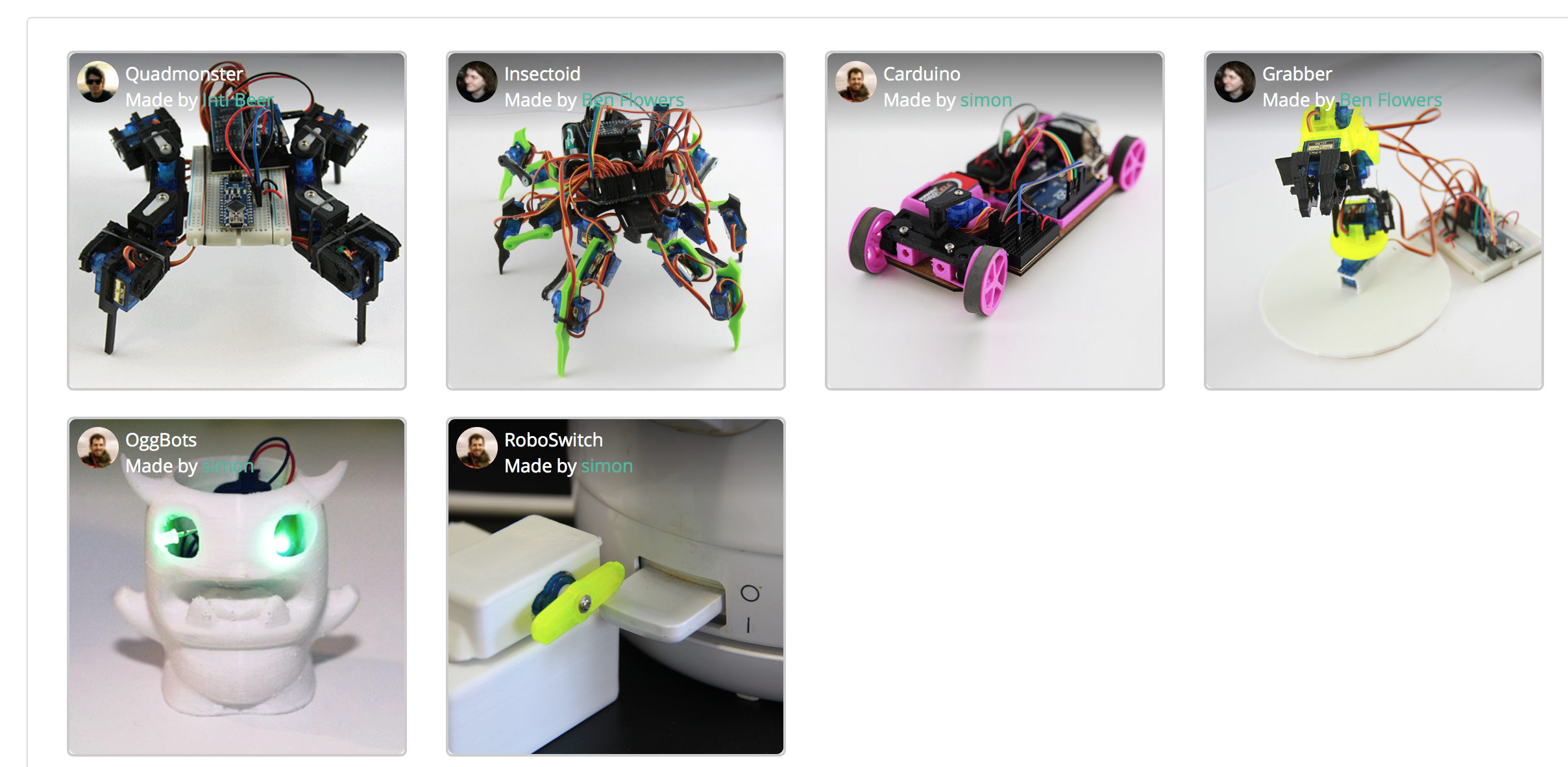

Want to make a giant 3D-printed spider robot? A humanoid help-mate? A robotic scorpion with a powerful, electrified tail? Makerclub can probably help. Created as a place for makers to come together and discuss 3D printed robotics, the service is now part commerce site, part repository, and part educational resource. Interestingly, the service is also offering a hardware brain on Indiegogo to help build the creations.

“As far as we know, no-one else is creating a 3D printed library of parts such as ours, or building an educational platform to bring the technology to the mainstream,” said the founder Simon Riley.

Reilly has also created a board, called the MakerConnect, that makes it easy to build the creations on the site. Called the MakerConnect, it connects an Arduino board with on-board Bluetooth so you can wirelessly control the creations on the site. While you don’t need to use the MakerConnect, the $50 board makes it much easier to build many of the robots on the site.

“We create 3D printed robotics projects which teach invention and product design. Each project is powered by our Arduino based chip, and controlled by your smartphone,” said Rielly. Users can download plans and programs and then print all the parts needed for the robots. There are even lesson plans using the models so kids can learn how to create robotic projects with a minimum of fuss.

“I studied Electronic Engineering with Computing at Nottingham, with my 3rd year in UNSW, and then went into Software Development,” said Rielly. “I’ve worked for a number of companies, big and small, including Experian, eBay and Brandwatch and have become a relatively proficient programmer. However, it always niggled me that I came out of University with a 2:1 and almost no real understanding of or passion for my subject, and I had to spend the next 5 years catching up before and after work.”

“This all started from my frustrated efforts to make a remote controlled car 2 years ago. I could work out how to program everything but my woodwork and general craft skills are so below par, that everything I made would either fall apart or be so clunky that nothing would move. I was then lucky enough to meet up with my old boss at a Christmas party where we discussed the beginnings of my idea and get brought a 3D printer for my combined Christmas and Birthday Present two weeks later,” he said.

Reilly describes the project as “everything I would have wanted as a 15-year-old kid.” Throw in some Stephen King books and a Victoria’s Secret catalog and I think he might be right.

No comments:

Post a Comment