The Formlabs Form 1+ is a $3,299 stereolithography 3D printing machine that takes up a large chunk of desk space, and takes a similarly sizeable bite out of your savings. But what if there’s another way to get your hands on this type of 3D printing tech? Well, say hello to the teeny gizmo in the above video.

The iBox Nano, shown in time-lapse 3D-printing a chess piece, uses a similar type of 3D printing technology to Formlabs’ printers — specifically the Nano uses UV LEDs to cure resin prints — but it has a price-tag of just $299 because it’s small enough to hold in the palm of your hand.

Resin 3D printers differ to FDM (filament) printers, which extrude (typically) plastic filament to build up prints. Resin is better suited to finer detail than FDM, making the Nano’s focus on printing small objects appropriate.

The printer is powered by a low cost microcomputer Raspberry Pi, encased in a laser-cut clear acrylic box to save on manufacturing costs by doing away with the need for any injection moulding. Every little helps, as they say.

What’s the point of a really small 3D printer? The world’s smallest, the Nano’s Florida-based makers claims. They argue small is beautiful when it comes to 3D printers because costs come down on all fronts: the printer unit itself, the cost of the materials required to fulfill a print job, and the wait time for printing the object out.

Energy consumption is also cut down to size, and operational noise levels are reduced.

Founder Trent Carter says part of its market research involved polling around 100 households that have used 3D printers in the past 12 months, and it found most people “only print small things”.

“The reasons seem to stem from the long build times for large items, sometimes 10-12hours, and moderate cost of materials for 3D printing. If you have a printer that prints 4x4x4” and print an object that size it could take 14-18 hours and consume $30-60 of consumables. This varies based on the speed of the printer and the print material,” he tells TechCrunch.

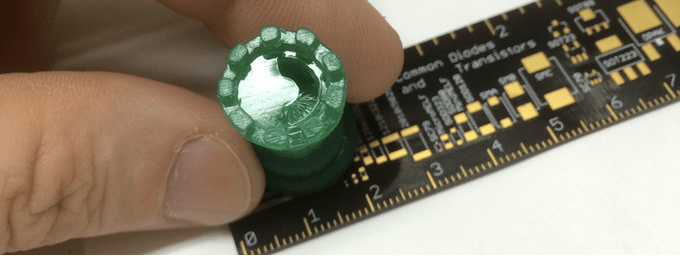

“As you can see it is expensive and slow to print large objects. In contrast the Rook that you see printed in our video and in our closeup images measures 30mm x 20mm and took about 2 hours to print and consumed about 50 cents worth of resin!”

In terms of what exactly can be printed with such a dinky printer, Carter suggested items such as small models, jewelry, game pieces and toys, and small replacement parts. It is also possible to create larger items by printing them piecemeal and assembling into a large construction afterwards, using screws or glue.

The Nano’s maximum print resolution is 0.39 microns on the Z axis. (The smaller the number here the less banding on print outs.) Although printing at that ultra high resolution would increase the printing time, so it supports 100 microns if you want a quicker print. The total build area is 40 x 20 x 90mm.

Carter and co are currently raising crowdfunding on Kickstarter to turn their prototype into commercial shipping product. At the time of writing they are north of $275,000 raised, with a funding goal of $300,000 and 11 days left on their campaign.

Although they’re on Kickstarter the project is fairly well advanced at this point, with Carter noting that they have completed work on the Nano’s hardware — and have multiple alpha and beta units printing.

Extant work to complete before their shipping schedule of April 2015 is continued hardware testing of the beta production run of 100 units, and software dev work — including creating printing profiles for supported resins.

“The software is functional and being debugged and improved daily. We are adding features and testing. Because the software can be updated post-purchase there is little risk to our shipping schedule,” he says.

“A 3D printer needs a ‘Profile’ for every Resin supported, and for different build qualities such as layer thickness. We are adding these as they get through Q&A. Because these profiles can be downloaded from our site or from other users, we see little risk to our schedule. We have several Profiles finished today. More will be added as they become tested and certified.”

iBox Nano is not the first 3D printer maker to try shrinking the tech to cut the price tag down to a more consumer-friendly size. Earlier this year The Micro 3D printer raised more than $3 million on Kickstarter promising a compact FDM printer starting at $299, with a build area of 4.6 x 4.2 x 4.4″.

No comments:

Post a Comment